Strong Equipment

Pad printing plate Oil steel 600x600x13mm

Product advantages: it has the characteristics of hardening ability and wear resistance, never deforming, good processability and fine structure. (hardening and wear resistance, good machinability, fine structure)

View DetailsStrong Injection Moulding Machine Die Casting Machine Pin Shaft Steel Sleeve

Carburizing , Nitridation , Strong Injection Moulding Machine Die Casting Machine Pin Shaft Steel Sleeve , Pin Shaft

View DetailsPeople, goods, yards and warehouses are facing digital and intelligent upgrading: calculated by data and managed by systems. Artificial intelligence and loT will play a huge role in the field of warehousing and logistics. Future technology will inevitably bring about industrial innovation and change.

View DetailsAmmonia decomposition device used in small laboratory

Small ammonia decomposing furnace, suitable for laboratory atmosphere furnace. The gas production capacity is 1 ~ 5m³ / h, which is precise and controllable.

View DetailsAmmonia Cracker (100~180 cubic)

Ammonia Cracker (100~180 cubic) , Decomposed the ammonia , metallicmaterial gas sheilding welding , metal bright heat treatment

View DetailsAmmonia Cracker (20 ~ 100 cubic)

Ammonia Cracker , Decomposed the ammonia , powder metallurgy agglomeration

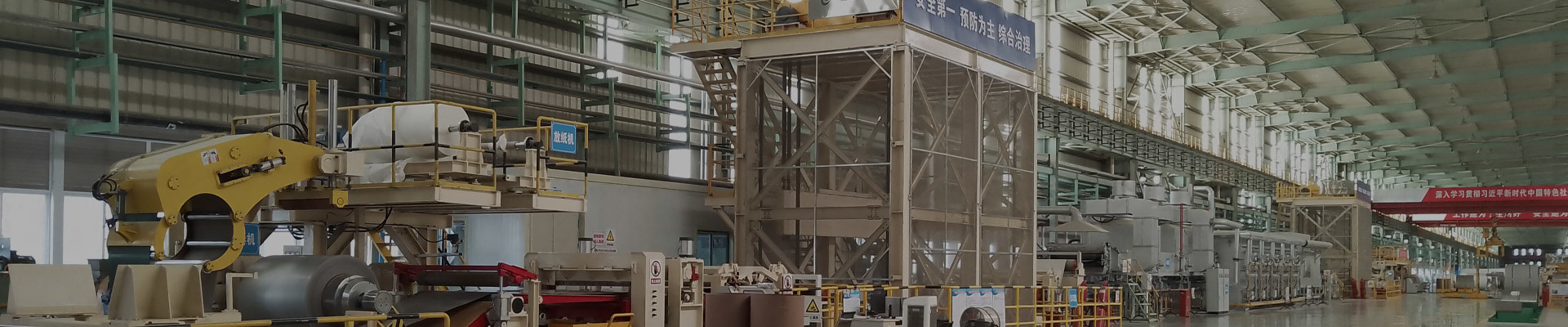

View DetailsIntelligent heat treatment production line

The intelligent heat treatment production line is specially designed for the carburizing, homogen and other processes of long shaft workpieces, and is applied to automobile shaft, high-speed railway shaft, subway shaft, special digging machine and other industries.

View DetailsSurface precision treatment equipment

The equipment consists of: computer control and management system, salt quenching tank, main furnace, salt washing machine, transfer table, loading and unloading table, manipulator, exhaust hood, electrical control system, gas control system, loading material, etc.

View Details